Our Customers

Our long-length machining centers are primarily used in the following industries. This page introduces some of our major clients in these sectors.

Clients

Taguchi craftech co.,ltd

2024 Installations (Repeat Clients)

Back ground

The company designs and manufactures cases for packing speakers and audio equipment. Because they produce specialized products, it is challenging to find machines that fit their processing needs with general specifications. They discovered our company, which offers detailed customizations, and decided to implement our long-length machining centers. They have been using a machine from over 20 years ago and recently decided to expand to a two-machine production system. Thus, they have introduced a second machine with new specifications.

Proposal

Based on the current model you have implemented, we gathered your detailed requirements and made necessary adjustments by adding essential functions and revising unnecessary ones. We proposed a long-length machining center that meets your expectations. With the two-machine system, you can not only increase production but also ensure continuous product supply even if one machine encounters an issue, thus maintaining uninterrupted production.

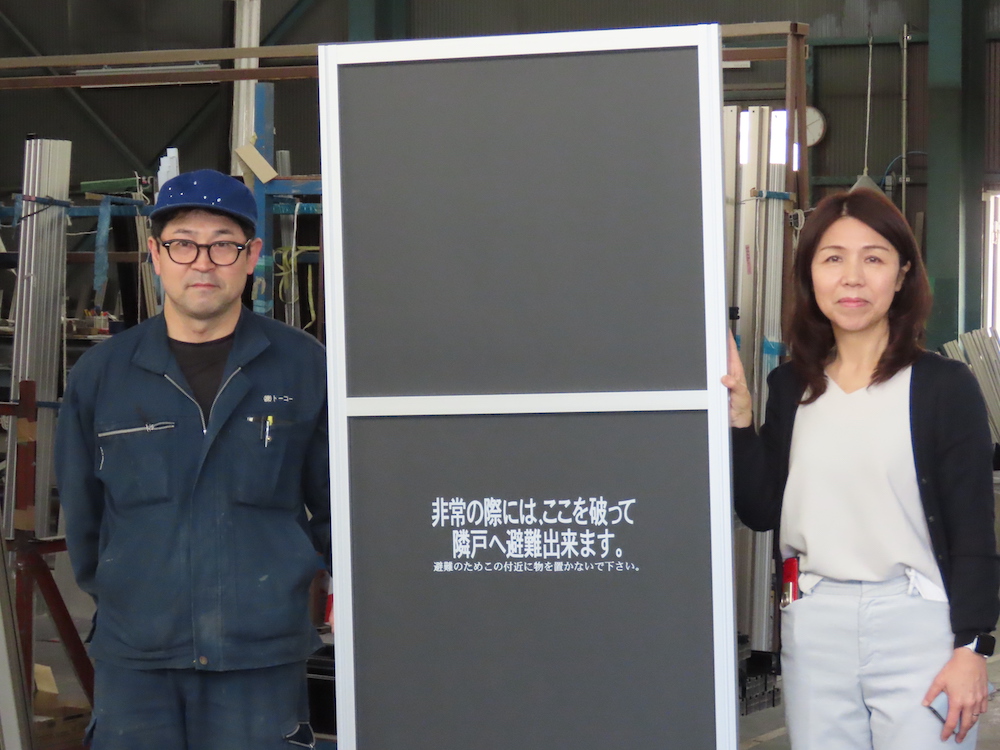

Toko co.,ltd

2023 Installations

Background

As the standard sizes of partitions increased, the types and precision of machining required also grew, necessitating the use of machinery, which led to the decision to implement our system. Additionally, with the increase in order volume, the previous methods could no longer keep up with production demands, prompting the introduction of our long-length machining center.

After Implementation

Not only did the accuracy improve and productivity increase significantly, but as the safety and strength requirements for the partitions grew, each panel became heavier. Our long-length machining centers played a crucial role in processing these heavier panels as well.

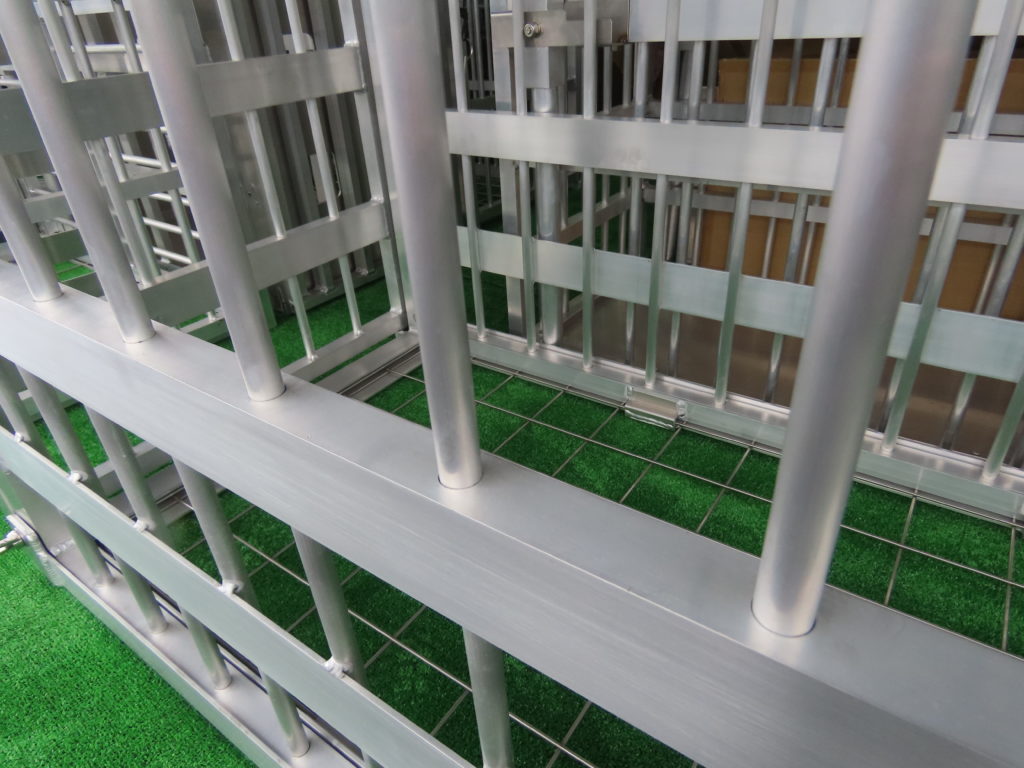

KOWA SEISAKUJO co.,ltd

2023 Installations

Background

In order to secure the Business Restructuring Subsidy, they aimed to enhance their capacity for long-length machining and considered entering new fields. Long-length items such as handrails and bus shelters are among these new ventures.

After Implementation

They have been using the machine to expand into new fields, increasing their machining capability from 2 meters to now being able to handle up to 6 meters. Consequently, there has been an increase in projects for 6-meter handrails and bus shelters.

Additionally, this required a factory that could accommodate 6-meter machines and a warehouse for storing the products, leading to the establishment of a new factory.

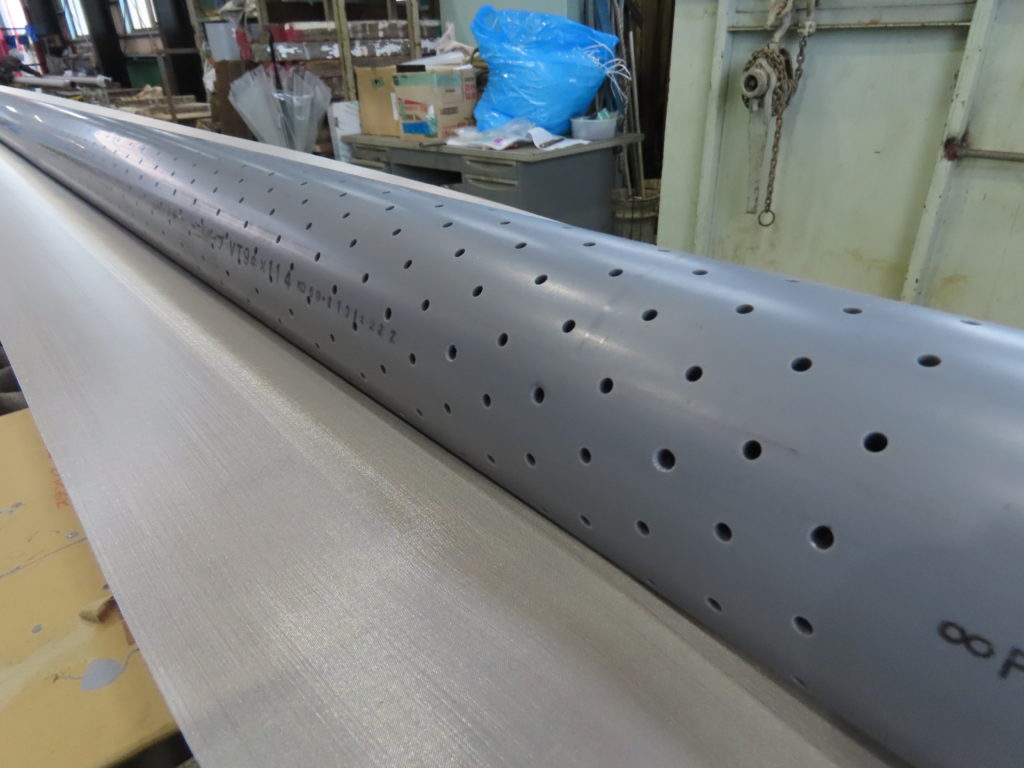

Boso plant co.,ltd

2013 Installations

Background

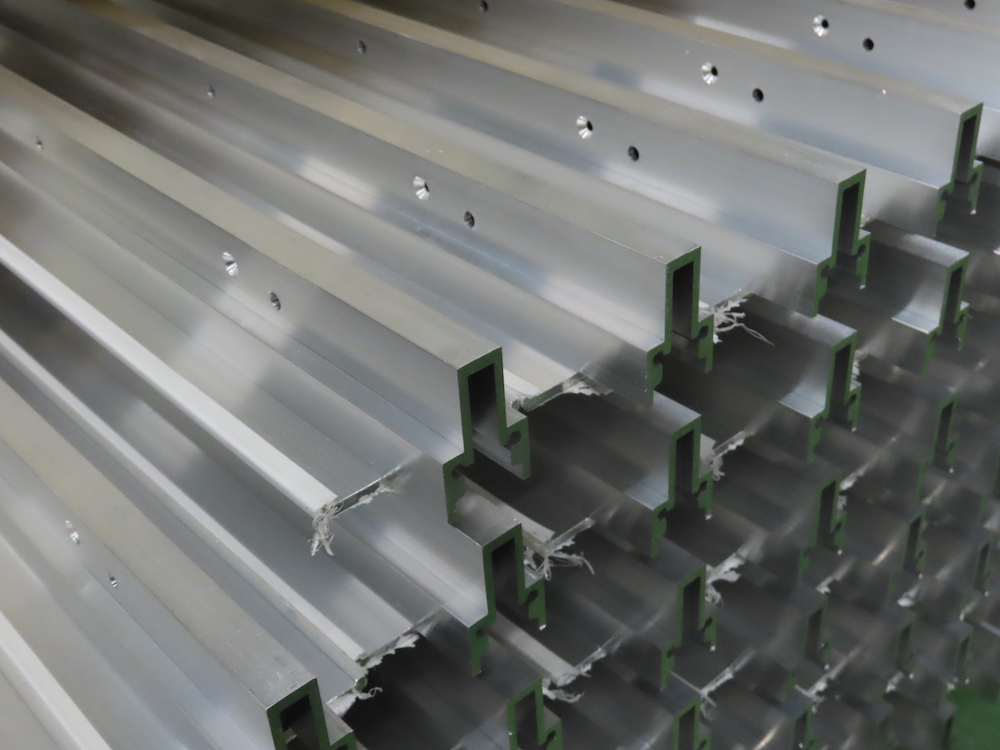

The company manufactures ladders and carts for a certain manufacturer, as well as their own original animal trap boxes.

Since these aluminum materials require numerous holes, the workload could not be met with drill presses and manual labor, leading to the decision to implement long-length machining centers.

After Implementation

In addition to increasing production volume and improving accuracy, this machining center is easy to operate, making it accessible to a wide range of users.

We received feedback that even temporary staff were able to master the operation by the end of their first day, which has been incredibly helpful.

Boso Plant has introduced a total of five machines: four long-length machining centers and one cutting machine.

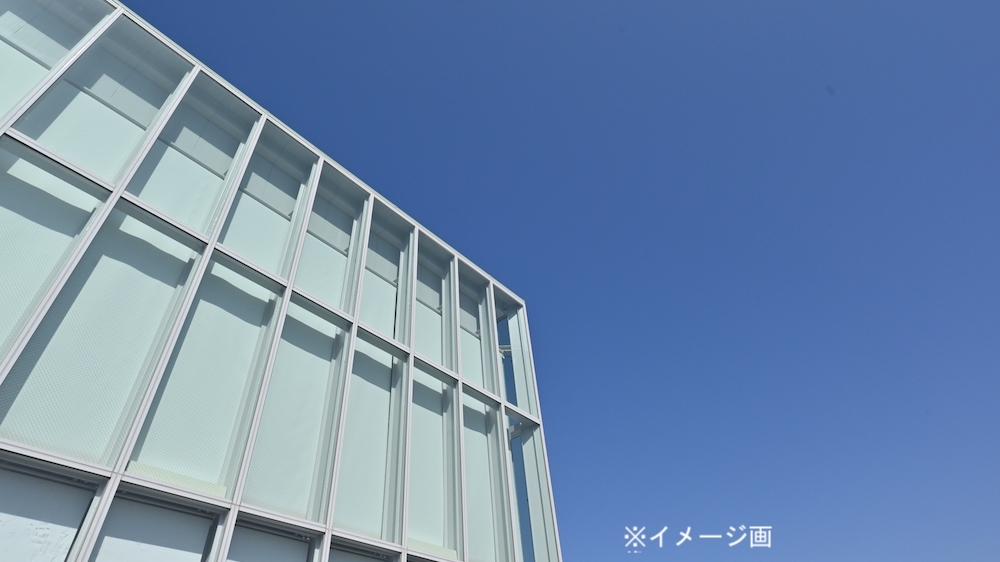

Fudai co.,ltd

2019 Installations

Back ground

The company manufactures curtain walls. Previously, they used drill presses for processing, which resulted in low productivity and inconsistent accuracy. They sought improvements in these areas.

Proposal

We proposed a model that performs both machining and cutting processes in a single machine. This machine is capable of various processes, including drilling, milling, cutting, and tenoning.

As a result, processing time was halved compared to before the introduction, and accuracy was standardized.

The greatest benefit, as evaluated by our client, was achieving product uniformity without relying on individual operators.

Shizuoka kinzoku kogyo co.,ltd

2022 Installations

Back ground

The company manufactures desks and lifts using aluminum extrusions. Initially, they thought it would be difficult to install a machine due to limited space.

However, with recommendations from the manufacturer, the introduction of an NC long-length machining center became necessary. Despite this, they couldn’t secure the installation space because the factory was too small.

Proposal

We conducted a detailed on-site assessment and measurements, and proposed the FBH25AL-6T. This model is compact and equipped with casters, allowing for easy layout changes after installation and flexibility in placement.

By successfully introducing the NC long-length machining center, which was initially thought to be difficult, the company saw improvements in productivity, accuracy, speed, safety, noise levels, and operator issues.

TETSU co.,ltd

2022 Installations

Background

The company, which processes construction steel materials, received an increasing variety of processing requests from customers every year. They struggled to handle these requests with their own resources and resorted to outsourcing, but found it economically unfeasible.

Proposal

To meet the demand for processing long holes in steel pipes and continuous drilling in H-beams and angles, we proposed the ‘high-torque type.’ Not only did this improve productivity, but it also ensured a consistently high level of quality, which was very gratifying.

Additionally, the machine’s ease of operation allowed even foreign workers to quickly learn and use it effectively.

Daiyasu kogyo co.,ltd

2022 Installations

Background

The company, which manufactures machine tool frames, previously used a laser processing machine for drilling holes in pipes. However, alignment was difficult and time-consuming. They also wanted to bring outsourced processing in-house.

Proposal

We proposed the standard model FB-5000-12ATC, which features a 5-meter specification and a 12-tool changer. This model is capable of drilling various sizes of holes, including continuous drilling.

As a result, work efficiency significantly improved, and the accuracy of long-length items, which had been a challenge, was greatly enhanced. This brought a great deal of satisfaction to the company.

-1024x768.jpg)